A layer that gives information on the part size and face to machine and layers that define the type of machining to do. Maestro needs 2 specific layer types to machine a part. To do this open a new post processor and in the Post Processor section choose DXF or OptiNest.

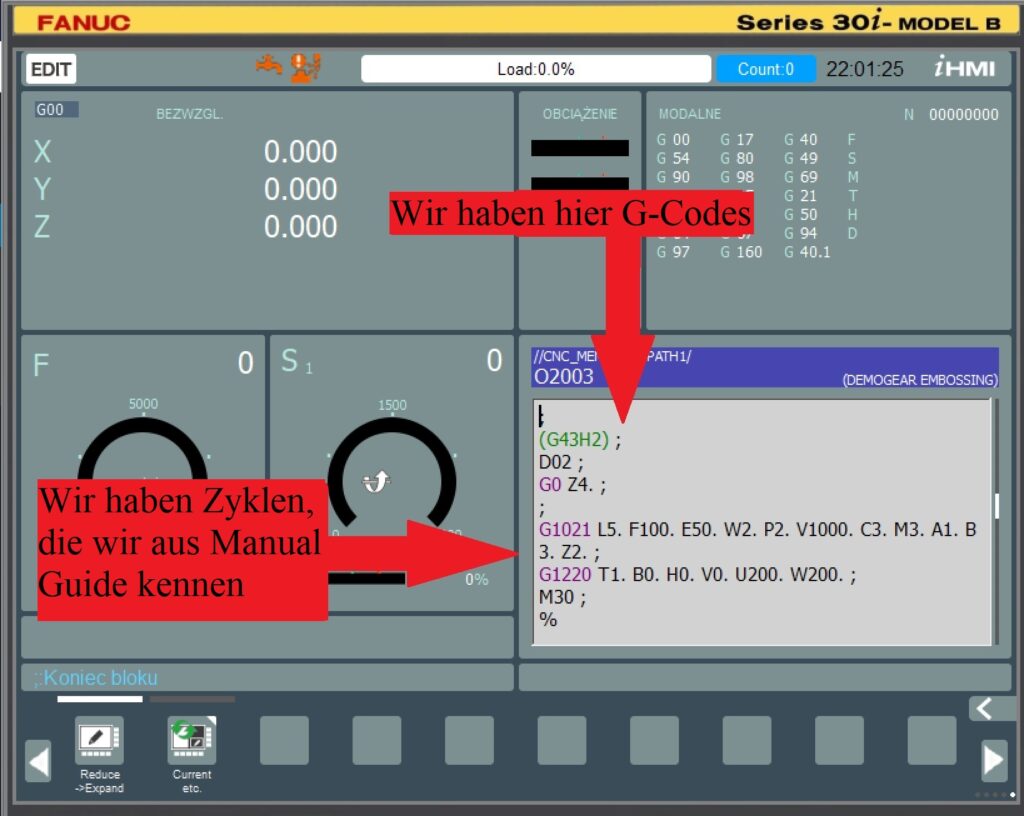

That Maestro contains the correct “Technology” file referenced in the DXF layer name.That the DXF file layers be named correctly.Maestro can import a DXF file and if the layer names are set up correctly Maestro can call and apply a “Technology” to the geometry that is on the layer.

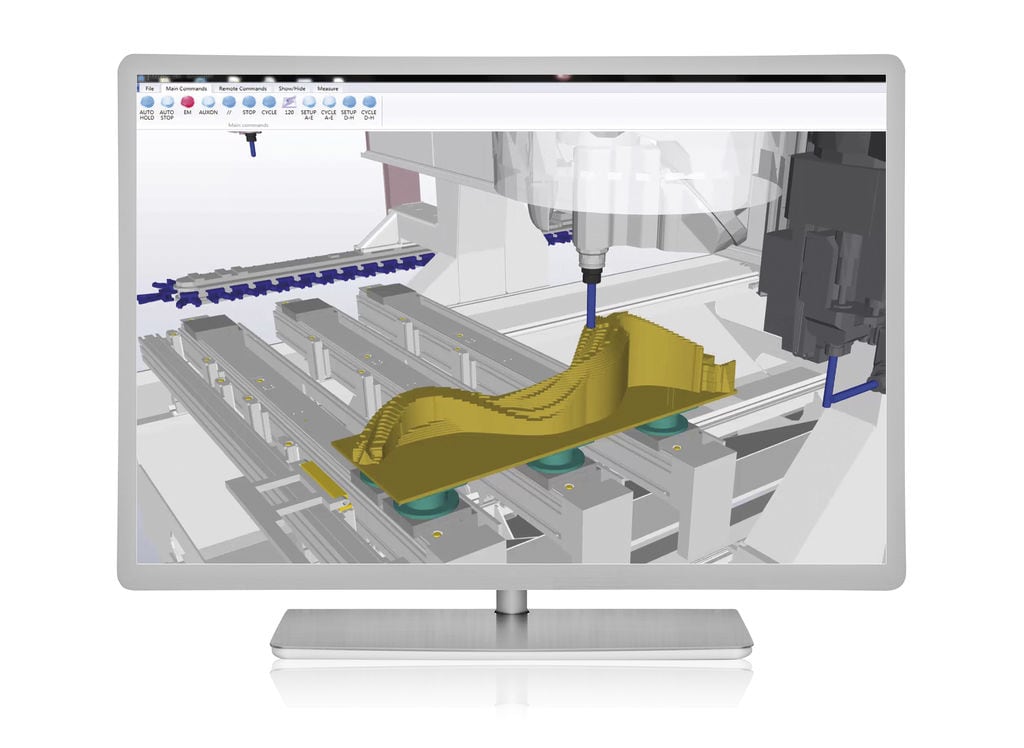

Please note that this guide only contains information for the DXF layer set up, for more information on the other post processor parameters please see our other resources. This can then loaded into Maestro to be automatically tool pathed.įor this to work the DXF file layer names must be set up so that MaestroĬan recognise the correct tooling to apply to the DXF geometry. OptiNest will create a new DXF nested file that contains all the parts optimised onto a sheet of material. The DXF set up is done in PolyBoard and automatically transferred to OptiNest. Maestro can import any DXF file and with a little set up also automatically apply the tool paths so that it’s easy and fast to simply load the OptiNest DXF into Maestro and create the machine file for a SCM CNC without manually applying tool paths. However when using a nesting machine with OptiNest it is necessary to use a DXF file to run the CNC machine. For SCM point to point CNC machines equipped with the CAM software Maestro, PolyBoard can export XXL files that can be read directly with Maestro.

0 kommentar(er)

0 kommentar(er)